FORGED CARBON STEEL GATE VALVE ASA 800 CLASS OUTSIDE SCREW & YOKE TYPE BOLTED BONNET

| BODY / BONNET | ASTMA105 |

| TRIMS | 13cr |

| MFG STD | API 602/BS 5352 |

| INSP & TEST STD | API 598/BS 6755 |

FORGED CARBON STEEL GATE VALVE ASA 1500 / 2500 CLASS OUTSIDE SCREW & YOKE TYPE BOLTED BONNET

| BODY / BONNET | ASTMA105 |

| TRIMS | 13cr |

| MFG STD | API 602 BS 5352 |

| INSP & TEST STD | API 598 BS 6755 |

| ENDS | SCREWED TO BSPT j NPT |

| HYD-TEST PRESSURE | BODY : 5400 Psig (379 KgjCm2) FOR 1500#, SEAT : 4000 Psig (281 KgiCm2 ) FOR 1500#, BODY : 9000 Psig (633 KgjCm2 ) FOR 2500#, SEAT : 6600 Psig (464 KgjCm2) FOR 2500#, SIZE RANGE : 15MM TO 40 MM |

FORGED CARBON STEEL GATE VALVE ASA 150 / 300 CLASS OUTSIDE SCREW & YOKE TYPE BOLTED BONNET

| BODY / BONNET | ASTMA 105 |

| TRIMS | 13Cr |

| MFG STD | API 6021BS 5352 |

| INSP & TEST STD | API 598 1BS 6755 |

| ENDS | FLANGED TOANSI B 16.5 RF (150#/300%#) |

| HYD-TEST PRESSURE | BODY: 425 Psig (30 Kg/Cm2) FOR 150#, SEAT : 300 Psig (21 KgjCm2 ) FOR 150#, BODY : 1100 Psig (77 KgiCm2) FOR 300#, SEAT : 800 Psig (56 KgjCm2 ) FOR 300# |

| SIZE RANGE | 15MM TO 50 MM |

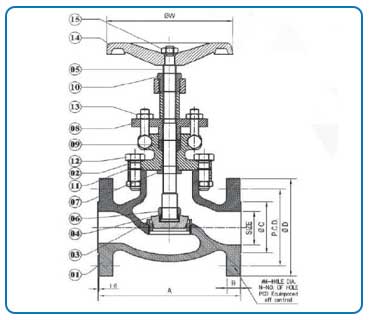

“SANKALP ENGINEERS”make globe valves is linear mation valve and are primarily deigned to stop, start and regulate flow. the disc of a globe valve can be totally removed from the flowpath or It can completely close flowpath

| NO | DESCRIPTION | MATERIAL | QTY. |

|---|---|---|---|

| 01 | BODY | ASTM A216 Gr. WCB / CF8 / CF8M | 1 |

| 02 | BONNET | ASTM A216 Gr. WCB / CF8 / CF8M | 1 |

| 03 | SEAT RING | AISI 410 (13% CR) SS 304 1 316 | 1 |

| 04 | DISC | AISI 410 (13% CR) SS 304 / 316 | 1 |

| 05 | STEM | AISI 410 (13% CR) SS 304 316 | 1 |

| 06 | STEM NUT | AISI 410 (13% CR) SS 304 316 | 1 |

| 07 | BACK SEAT | AISI 410 (13% CR) SS 304 / 316 | 1 |

| 08 | GLAND | CARBON STEEL | 1 |

| 09 | GLAND PACKING | METALIC WIRE REINFORCED GRAPHOIL ASBESTOS | |

| 10 | YOKE SLEEVE | SG IRON | 1 |

| 11 | BONNET GASKET | ASBESTOS FILTER S.S. 304 SPRIAL WOUNDED / CAF | 1 |

| 12 | BONNET STUD & NUT | ASTM A 193 Gr. B7 ASTM A 194 Gr. 2H | |

| 13 | EYE BOLT & NUT | ASTM A 193 Gr. B7 ASTM A 194 Gr. 2H | 2 SET |

| 14 | HAND WHEEL | SG IRON | 1 |

| 15 | HAND WHEEL NUT | CARBON STEEL | 1 |

| TECHNICAL DATA | |

|---|---|

| DESIGN & MANUFACTURING STD. | BS 1873 |

| TESTING & INSPECTION STD. | API 598 / BS 5146 |

| END CONNECTIONS : | FLANGED AS PER ANSI B-16.5 |

| SHELL WALL THICKNESS | AVSI B 16,34 |

| FACE TO FACE: : | AS PER ANSI / B 16.10 |

| No. | CLASS__1 | SERVICE WORKING PRES.__2 | & TEMP.__3 | TEST HYD. TEST BODY__4 | PRESS. SEAT__5 |

| 1. | 150 | 150 PSIG | 500°F | 425 PSIG | 300 PSIG |

| 2. | 300 | 300 PSIG | 800°F | 1100 PSIG | 800 PSIG |

| SIZE | CLASS - | 150 | |||||||

| IN. | M.M. | A | B | OD | OM | N | P.C.D. | ow | |

| 1" | 25 | 127 | 11.0 | 51 | 108.0 | 16 | 4 | 79.2 | 100 |

| 1.1/2" | 40 | 165 | 14.2 | 73 | 127.0 | 16 | 4 | 98.5 | 135 |

| 2" | 50 | 203 | 15.7 | 92 | 152.0 | 19 | 4 | 120,6 | 200 |

| 2.1/2" | 65 | 216 | 17.5 | 105 | 178.0 | 19 | 4 | 139.7 | 250 |

| 3" | 80 | 241 | 19.0 | 127 | 190.5 | 19 | 4 | 152.4 | 250 |

| 4" | 100 | 292 | 157 | 229.0 | 19 | 8 | 190.5 | 300 | |

| 5" | 125 | 356 | 24.0 | 186 | 254.0 | 22 | 8 | 215.9 | 350 |

| 6" | 150 | 406 | 25.0 | 216 | 279.0 | 22 | 8 | 241.3 | 350 |

| 8" | 200 | 495 | 28.5 | 270 | 343.0 | 22 | 8 | 298,4 | 400 |

| 10" | 250 | 622 | 30.0 | 324 | 406.0 | 25 | 12 | 362.0 | 450 |

| 12" | 300 | 698 | 32.0 | 381 | 483.0 | 25 | 12 | 431.8 | 500 |

| SIZE | CLASS | - | 300 | ||||||

| IN. | M.M. | A | B | OC | OD | OM | N | P.C.D. | OW |

| 1" | 25 | 203.0 | 17.5 | 51 | 124.0 | 19 | 4 | 89.0 | 135 |

| 1.1/2" | 40 | 229.0 | 20.5 | 73 | 155.5 | 22 | 4 | 114.3 | 200 |

| 2" | 50 | 267.0 | 22.0 | 92 | 165.0 | 19 | 8 | 127.0 | 200 |

| 2.1/2" | 65 | 292.0 | 25.0 | 105 | 190.5 | 22 | 8 | 149.3 | 200 |

| 3" | 80 | 317.5 | 28.5 | 127 | 209.5 | 22 | 8 | 168.0 | 300 |

| 4" | 100 | 356.0 | 32.0 | 157 | 254.0 | 22 | 8 | 200.0 | 350 |

| 5" | 125 | 400.0 | 35.0 | 186 | 279.4 | 22 | 8 | 235.0 | 350 |

| 6" | 150 | 444.5 | 36.5 | 216 | 317.5 | 22 | 12 | 269.7 | 400 |

| 8" | 200 | 559.0 | 41.0 | 270 | 381.0 | 25 | 12 | 330.2 | 550 |

| 10" | 250 | 622.0 | 47.5 | 324 | 444.5 | 28 | 16 | 387.4 | 600 |

| 12" | 300 | 711.0 | 51.0 | 381 | 521.0 | 32 | 16 | 450.8 | 600 |

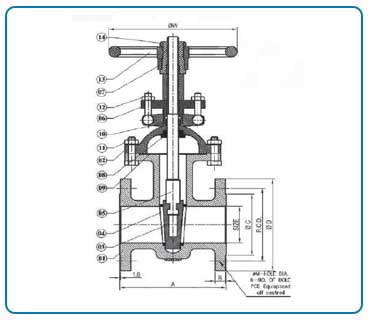

“SANKALP ENGINEERS”make globe valves is linear mation valve and are primarily deigned to stop, start and regulate flow. the disc of a globe valve can be totally removed from the flowpath or It can completely close flowpath

| NO | DESCRIPTION | MATERIAL | QTY. |

|---|---|---|---|

| 01 | BODY | ASTM A216 Gr. WCB / CF8 / CF8M | 1 |

| 02 | BONNET | ASTM A216 Gr. WCB / CF8 / CF8M | 1 |

| 03 | SEAT RING | AISI 410 (13% CR) SS 304 1 316 | 1 |

| 04 | DISC | AISI 410 (13% CR) SS 304 / 316 | 1 |

| 05 | STEM | AISI 410 (13% CR) SS 304 316 | 1 |

| 06 | STEM NUT | AISI 410 (13% CR) SS 304 316 | 1 |

| 07 | BACK SEAT | AISI 410 (13% CR) SS 304 / 316 | 1 |

| 08 | GLAND | CARBON STEEL | 1 |

| 09 | GLAND PACKING | METALIC WIRE REINFORCED GRAPHOIL ASBESTOS | |

| 10 | YOKE SLEEVE | SG IRON | 1 |

| 11 | BONNET GASKET | ASBESTOS FILTER S.S. 304 SPRIAL WOUNDED / CAF | 1 |

| 12 | BONNET STUD & NUT | ASTM A 193 Gr. B7 ASTM A 194 Gr. 2H | |

| 13 | EYE BOLT & NUT | ASTM A 193 Gr. B7 ASTM A 194 Gr. 2H | 2 SET |

| 14 | HAND WHEEL | SG IRON | 1 |

| 15 | HAND WHEEL NUT | CARBON STEEL | 1 |

| TECHNICAL DATA | |

|---|---|

| DESIGN & MANUFACTURING STD. | BS 1873 |

| TESTING & INSPECTION STD. | API 598 / BS 5146 |

| END CONNECTIONS : | FLANGED AS PER ANSI B-16.5 |

| SHELL WALL THICKNESS | AVSI B 16,34 |

| FACE TO FACE: : | AS PER ANSI / B 16.10 |

| No. | CLASS__1 | SERVICE WORKING PRES.__2 | & TEMP.__3 | TEST HYD. TEST BODY__4 | PRESS. SEAT__5 |

| 1. | 150 | 150 PSIG | 500°F | 425 PSIG | 300 PSIG |

| 2. | 300 | 300 PSIG | 800°F | 1100 PSIG | 800 PSIG |

| SIZE | CLASS - | 150 | |||||||

| IN. | M.M. | A | B | OD | OM | N | P.C.D. | ow | |

| 1" | 25 | 127 | 11.0 | 51 | 108.0 | 16 | 4 | 79.2 | 100 |

| 1.1/2" | 40 | 165 | 14.2 | 73 | 127.0 | 16 | 4 | 98.5 | 135 |

| 2" | 50 | 203 | 15.7 | 92 | 152.0 | 19 | 4 | 120,6 | 200 |

| 2.1/2" | 65 | 216 | 17.5 | 105 | 178.0 | 19 | 4 | 139.7 | 250 |

| 3" | 80 | 241 | 19.0 | 127 | 190.5 | 19 | 4 | 152.4 | 250 |

| 4" | 100 | 292 | 24.0< /td> | 157 | 229.0 | 19 | 8 | 190.5 | 300 |

| 5" | 125 | 356 | 24.0 | 186 | 254.0 | 22 | 8 | 215.9 | 350 |

| 6" | 150 | 406 | 25.0 | 216 | 279.0 | 22 | 8 | 241.3 | 350 |

| 8" | 200 | 495 | 28.5 | 270 | 343.0 | 22 | 8 | 298,4 | 400 |

| 10" | 250 | 622 | 30.0 | 324 | 406.0 | 25 | 12 | 362.0 | 450 |

| 12" | 300 | 698 | 32.0 | 381 | 483.0 | 25 | 12 | 431.8 | 500 |

| SIZE | CLASS | - | 300 | ||||||

| IN. | M.M. | A | B | OC | OD | OM | N | P.C.D. | OW |

| 1" | 25 | 203.0 | 17.5 | 51 | 124.0 | 19 | 4 | 89.0 | 135 |

| 1.1/2" | 40 | 229.0 | 20.5 | 73 | 155.5 | 22 | 4 | 114.3 | 200 |

| 2" | 50 | 267.0 | 22.0 | 92 | 165.0 | 19 | 8 | 127.0 | 200 |

| 2.1/2" | 65 | 292.0 | 25.0 | 105 | 190.5 | 22 | 8 | 149.3 | 200 |

| 3" | 80 | 317.5 | 28.5 | 127 | 209.5 | 22 | 8 | 168.0 | 300 |

| 4" | 100 | 356.0 | 32.0 | 157 | 254.0 | 22 | 8 | 200.0 | 350 |

| 5" | 125 | 400.0 | 35.0 | 186 | 279.4 | 22 | 8 | 235.0 | 350 |

| 6" | 150 | 444.5 | 36.5 | 216 | 317.5 | 22 | 12 | 269.7 | 400 |

| 8" | 200 | 559.0 | 41.0 | 270 | 381.0 | 25 | 12 | 330.2 | 550 |

| 10" | 250 | 622.0 | 47.5 | 324 | 444.5 | 28 | 16 | 387.4 | 600 |

| 12" | 300 | 711.0 | 51.0 | 381 | 521.0 | 32 | 16 | 450.8 | 600 |